You have no items in your shopping cart.

Besides fiberglass cloth and chopped strand mat, there are two other common types of fibers used in composites. One is carbon fiber, the other is aramid. Kelvar® is DuPont's brand name for aramid.

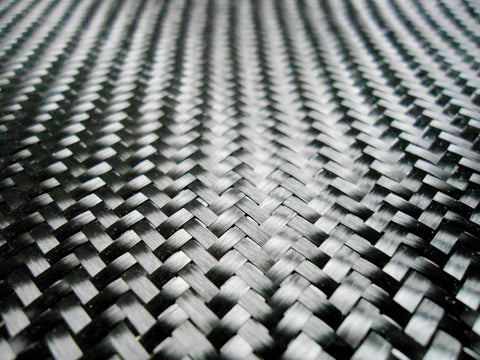

Carbon Fiber

Carbon fiber is known for its strength, being light weight and for its good looks. It is commonly used in the automobile, sporting goods and aerospace industry. A yard of carbon fiber cloth has millions of microscopic filaments all bundled together. For instance, in a 3k fiber fabric, each tow (or bundle) of fiber has 3000 filaments in it. The bundles are woven together to form a fabric. This is what makes it so strong. Each filament carries part of the load.

Inherently, by weight, carbon is much stronger than steel. But it still has its limitations. Carbon fiber is brittle. If a piece of steel is hit by a large rock, it will deform and bend. If a piece of carbon fiber laminate is hit with a large rock, chances are it will shatter and break. With that said, there are many instances where carbon fiber is more appropriate to use instead of metal.

In sporting goods, hockey sticks were first made of wood. They were good sticks and inexpensive. They felt good in your hands. In the 1980's, aluminum hockey shafts with wood blades were developed. They were strong and lasted longer than the wood, but they didn't feel great to play with. (Wayne Gretzky still used it though.) In the 1990's, carbon fiber hockey shafts were developed with a separate carbon fiber or Kevlar hockey blade. Many people liked these. They were durable and light weight, but still lacked the feel of a one-piece wood stick. In the 2000's the one-piece carbon fiber hockey sticks started coming out. People had the feel of the one-piece wood stick, but the all carbon stick was extremely responsive, light and strong. It now dominates the NHL. The only problem is that they are much more expensive than a wood hockey stick. In cars, carbon fiber fabric is used to make hoods and dashboards. Usually, the carbon fiber is only there for its looks. It doesn't add strength or durability. It looks awesome though. Especially when it has a glossy clear coat on top of it. If there is a part that needs to be made with carbon fiber, typically it is made with carbon fiber uni-direction material. The reason is that it is much cheaper than the cloth.

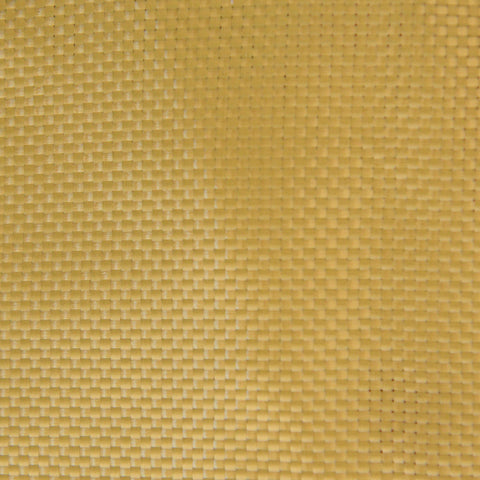

Kevlar®

Kevlar® is known for its impact and abrasion resistance. It has great tensile strength, but poor compression strength. It can also be very hard to cut. Kevlar® is used in bullet-proof vests, motorcycle racing cloth and gloves. Many types of armor also uses Kevlar®. Anything that needs abrasion resistance probably uses Kevlar®.

Kevlar® was developed by DuPont during the 1970's. They were trying to develop a replacement for steel in tires. It was the first organic material that could be used in composites.

It is best to use epoxy or vinyl ester resin with Kevlar®. It is also a good idea to use a separate pair of scissors when cutting it.

More Options

Want to hear about more fiberglass reinforcements on the market? You can check out our Ultimate Fiberglass and Resin Guidebook HERE

comments (3)

-

-

DexCraft Carbon Fiber Manufacturing

DexCraft Carbon Fiber ManufacturingIt’s truly amazing how versatile carbon fiber is and how popular it has become. Nice post!

-

Jesse Fonseca

Jesse FonsecaBuilding a carbon fiber shaft for a stand up paddle . Broke 3-4 paddle already so wanted to build my own. Weigh does sort of matter but more concern in strength. What materials would best fit my application? Thinking about using 12k 2×2 twill and unidirectional carbon 22.3oz. Would this be best for strength? Or would mixing twill and 3k plain weave stronger ?

Thanks

JesseREPLY from fgwarehouse: That should work just fine. Make sure you use a good epoxy resin. You may also want to look at braided carbon, as it would slip over the shaft nicely.

REPLY from Jesse: Which would be a stronger combination? unidirectional or plain weave with twill?

REPLY from fgwarehouse: It depends on where the stresses are in the part. If the stress runs longitudinally, the uni. If it is laterally, then plain weave.

Hi Guyz, I still use 2-Piece hockey sticks and I want to learn how to epoxy/resin, carbon fiber my wooden hockey blades. …(or how you think I should go about doing this). The wooden blades insert into a shaft. I studied your website to educate myself and now I want to give it a try as I have about 20 partially broken wooden hockey blades to repair. Can you help me, give me advice on how to do this and/or which of your products I might use? Thanks for all the educational information at your website on how to use your products. Happy New Year and take care, Jimmy B. #93