You have no items in your shopping cart.

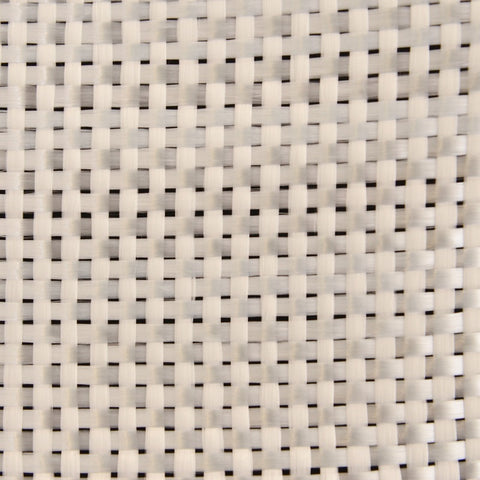

Woven Roving

Woven roving is a great option to use in boat building, especially when used with chopped strand mat. Woven roving is a heavy, coarse plain weave cloth. Bundles of roving are woven together loosely at 90 degrees. It comes in 18 and 24 oz weights. (We only sell the 24 oz woven roving by the yard).

Woven roving is used to quickly build up thickness. The continuous filaments add strength. A drawback is that with the woven bundles there is crimping. The crimp points can fracture.

Typically when using woven roving, it is alternately layered with chopped strand mat. The reason to use mat with roving is because of the knobbiness (bumpiness) of the roving. It is hard to adhere another layer of roving or cloth to it. There will be many voids left behind if done so. It will also be really heavy from the extra resin needed to fill in those voids.

Using woven roving is a great way to build up strength and thickness in a laminate. It can be heavy, though.

Knitted Fabric

Knitted fabric is also a great option in boat building and in the composite industry. The most common knitted fabric is DBM 1708. The 1708 is a 17 ounce +/-45 bias fabric with a 3/4 ounce chopped strand mat stitched to it.

Knitted fabric is bundled and stitched together. It provides maximum directional strength and wets out fast. It saves time in multi-layer layups. There is no crimping since the fabric is stitched instead of woven.

Knitted fabric is compatible with polyester, vinyl ester and epoxy resin.

More Options

Want to hear about more fiberglass reinforcements on the market? You can check out our Ultimate Fiberglass and Resin Guidebook HERE

If you have any questions, don't hesitate to email us at sales@fiberglasswarehouse.com or call 833-669-7899.

comments (2)

-

-

Jack Korvink

Jack KorvinkHave two halves of a circle to lay on top a smaller table to accomandate more seating. My question is when the top is not in use and in order to store it how can I use fiber material so the two halves close one against the other.

Thank you for you reply.REPLY from fgwarehouse: Hey Jack, are you trying to adhere the two halves together to make a complete circle? And just lay the new circular table top on the old table when needed?

REPLY from Jack Korvink: Yes, by the way the two halves are 1/4 plywood. Thank you.

REPLY from fgwarehouse: Typically when you bond two halves together, you want to put cloth and resin on both sides. Since this is a table top, you can only do one side. You will need to make the laminate on the bottom strong enough that it won’t bend. If it bends in the middle, the fiberglass will want to peel away of the plywood. So with that said, I would try and use 2 layers of our Knitted Fabric 1708. It is very strong and I think two layers should keep it from bending too much. As far as epoxy, I would use 1200 epoxy resin and 2:1 epoxy hardener.

You could also put one layer of 6 oz fiberglass cloth on both side of the plywood with the epoxy. This will make a nice looking table top. The 6 oz cloth should wet out transparent, and you will see the grain of the wood below.

Will I still to be able to fold the two halves together for storage if I use your suggestion of the knitted fabric on one side and then use the resin and hardener over the material except at the middle were the two halves meet.

Thank you.

REPLY from fgwarehouse: No you won’t. I didn’t realize you wanted to fold them. You will need to use a cloth fabric if you want to do that. Probably something like a fleece, or felt. You can still use resin to adhere it to the two halves.