You have no items in your shopping cart.

Our custom-colored gel coats are a superior grade ISO NPG resin that have good weather, heat and water resistance. They come in a variety of 72 different colors, Our custom colored gel coats create high quality finished parts and provide a durable protective surface. It polishes to a high gloss finish...

Check out this stunning display of craftsmanship and aeronautical history that our customer David sent to us. It is amazing to see what our customers create with our products! Here is what David said about his model- "I used your 0.75 fiberglass cloth to redo the airframe to represent a...

For DIY enthusiasts and crafters alike, deep pour epoxy resin has become a sought-after material for its versatility, durability, and the ability to pour in thicker layers. Whether you're embedding beloved objects or creating stunning river tables, epoxy resin allows for a boundless realm of creativity. However, working with this material can...

Customer Spotlight Our talented customer, Richard, sent us some photos of a stunning wooden kayak he created using our 6 ounce x 50" fiberglass cloth. This was an impressive project. The craftmanship is absolutely beautiful! Six Ounce Fiberglass Cloth Looking for a versatile and high-performance fiberglass cloth for your projects?...

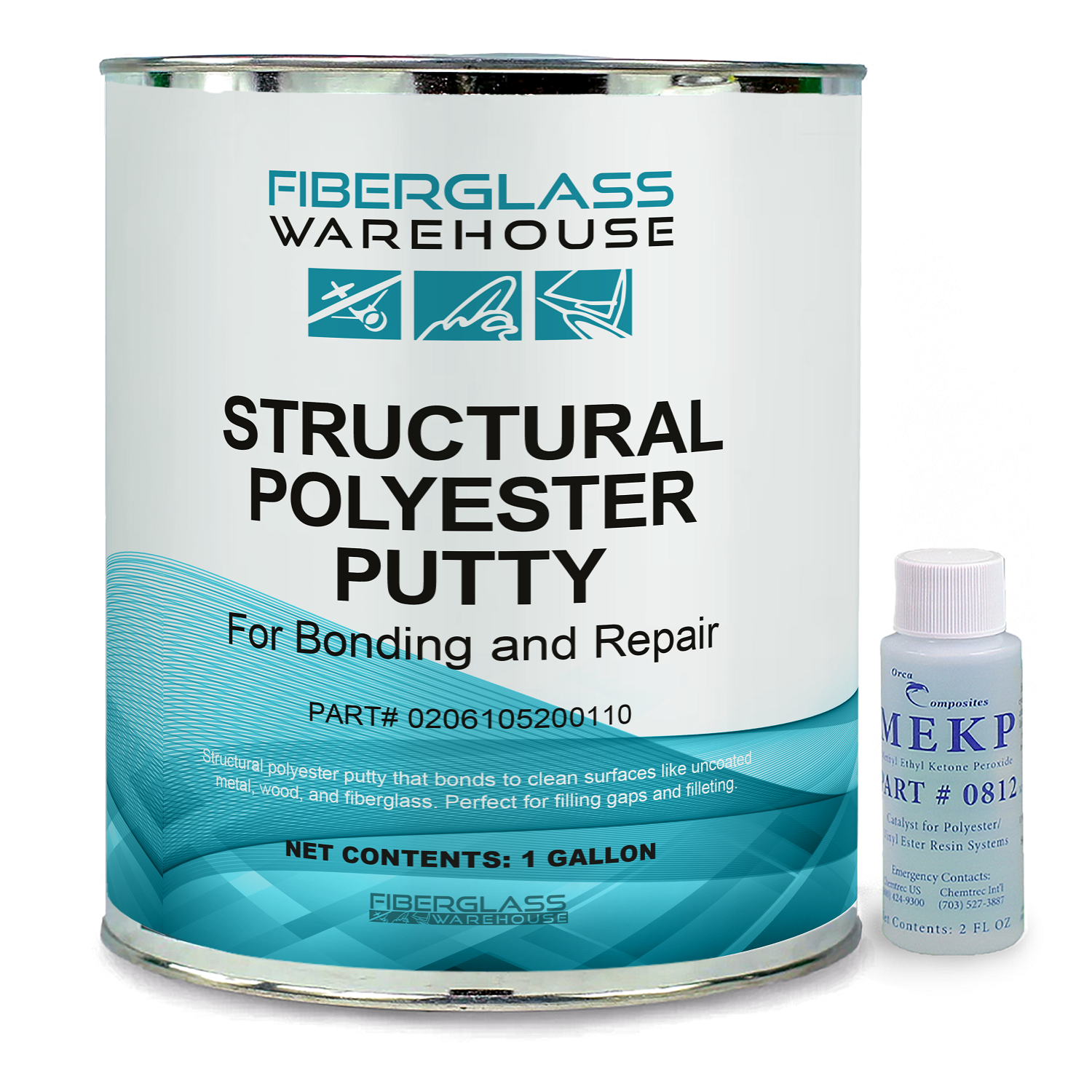

Structural Bonding Putty Details: Fiberglass Warehouse Structural Polyester Bonding Putty is your go to for bonding and repair. This medium weight, two-component polyester putty is ideal for boat building, automotive and general-purpose composite projects. This putty includes premium grade polyester resin with added glass fibers that goes on smooth without...

Marcus with Florida Custom Woods shared some amazing charcuterie boards he made using ProGlas 1105 Deep Pour Epoxy Resin. He uses stunning slabs of wood and a variety of different pigments with the epoxy resin. Each one is unique and shows off amazing craftsmanship. We love when our customers share their projects with us!...

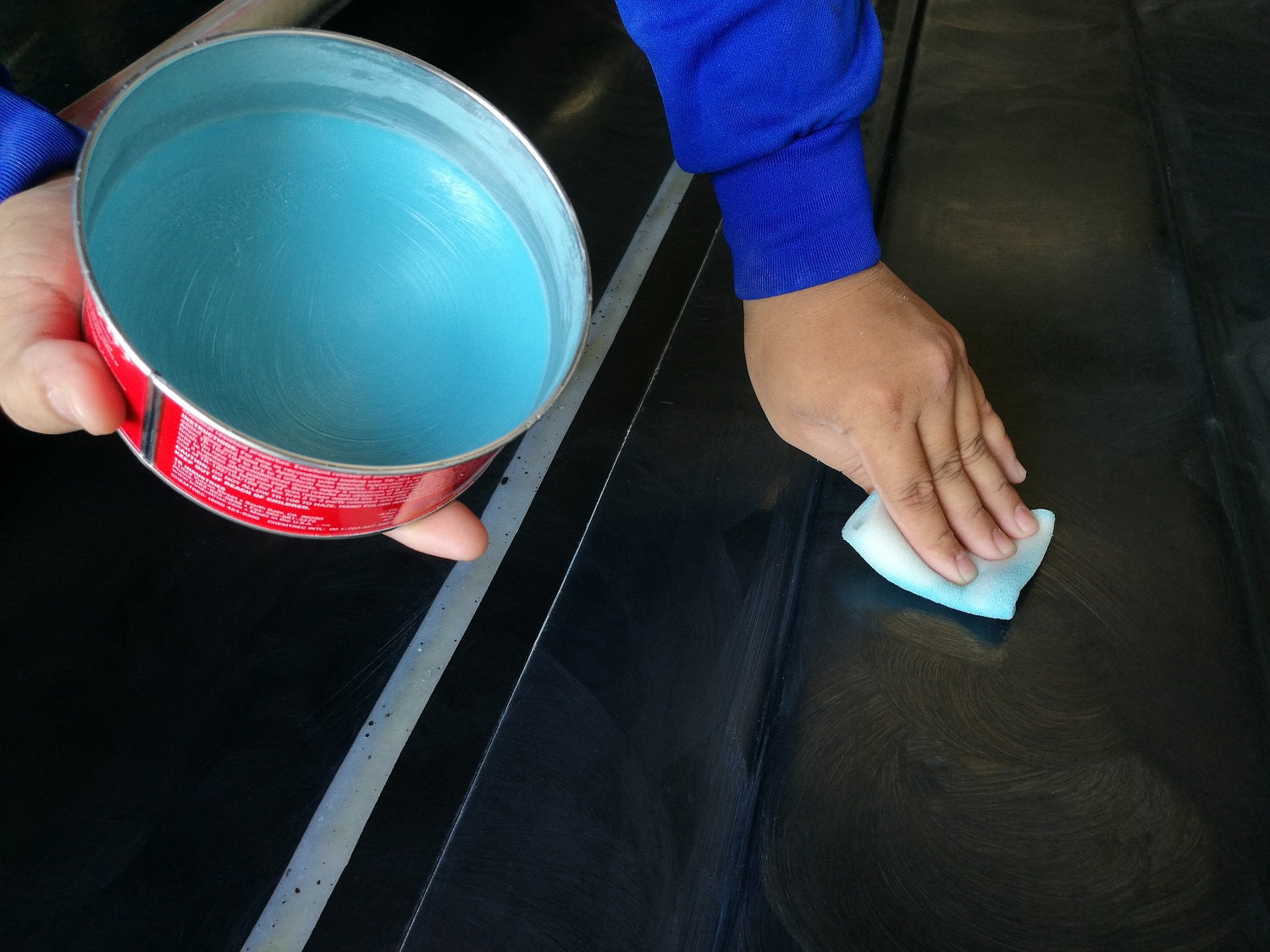

Maximizing your Mold: Exploring Popular Release Agents for Fiberglass Molds Composite craftsmen and makers in the DIY and hobbyist communities often share a common focal point – the mastery of fiberglass molding. But no matter how intricate your design or how meticulous your technique, the success of your project often...

Fumed Silica Filler Details Fumed silica is a very fine powder that acts as an efficient thickening agent, ideal for use with various resin types such as polyester, vinyl ester, or epoxy. Its primary functions includes creating fillet putty and enhancing the viscosity of resin to improve its performance as an...

In the world of crafting, there is something undeniably magical about turning raw materials into art. Today, we're excited to showcase the beautiful creations of Cleide, one of our own customers, who has transformed our Fiberglass Warehouse Clear Casting Resin into beautiful pendants that are a testament to her creativity and skill. Each...

Epoxy resin has taken the crafting world by storm, and for good reason. Its versatility and the stunning results it can produce make it an essential material for any DIY enthusiast, crafter, or hobbyist. In this showcase, we are thrilled to present the inspiring works of D&R Wood Slab Designs....

When the calm of the water or the open road is interrupted by an unexpected tear or hole in your fiberglass vessel or vehicle, it’s not the end of the world – it's the start of a hands-on repair that can restore your prized possession to its former glory. Whether...

Is your pool needing a refresh? With Spring coming soon, now is the time to start preparing to re-surface that pool! Our pool customers are the best at sending us pics to share. The below photos are from one of our pool companies that recently re-surfaced a hotel pool. It turned out...