You have no items in your shopping cart.

- Corrosive resistance

- Fast wet out

- Thixotropic

- Superior adhesion property

- Cures at room temperature with addition of MEKP

- Ships within one business day

Details:

Vinyl Ester laminating resin is a tough resin with high impact strength. It creates lightweight finished parts that have increased strength, fatigue life, high temperature capabilities and good corrosion resistance to acids, alkalis and oxidizing chemicals. It also, demonstrates adhesive properties making it ideal for secondary bonding applications. Vinyl ester laminating resin cures with a surface tack. Pre-promoted for curing at room temperature with the addition of methyl ethyl ketone peroxide (MEKP) initiator.

Uses:

-Boat construction and repair

-Molding, fabrication and repair of fiberglass laminates

-Spray up process

-Hand lay-up application

-Where higher strength, better elongation or more corrosion resistance is needed.

Application:

-Work area and resin should be between 70°F and 85°F for best results.

-Make sure the work area is well ventilated and wear proper safety clothing including gloves and a face mask.

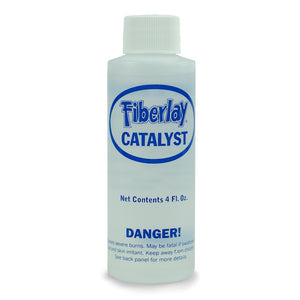

-MEKP catalyst is needed for vinyl ester resin to cure. It should be added between 1-2% based on the volume of the resin. More or less than this will cause an improper cure. Cure time and pot life will vary depending on percentage of MEKP added and the temperature of the room. If 1% MEKP is added, there will be a longer pot life and it will cure slower than if 1.5% or 2% MEKP is added. Same goes for temperature. Lower temperatures result in a slower pot life/cure time than if working in higher temperatures. Our vinyl ester resin is promoted to gel in 17-23 minutes at 77°F when catalyzed at 1 percent (approx. 1 tsp per pint). See our MEKP catalyst quantity chart HERE.

-Apply using a fiberglass roller, brush, spreader or squeegee

-No need for sanding between layers

-For the final layer, a surface seal can be added to create a hard, tack-free surface. The wax will rise to the top when cured and seals off the air.

Other Notes:

-Vinyl Ester Laminating Resin will yellow over time. It can be used under a colored gel coat if color is an issue.

-Uncured Vinyl Ester Laminating Resin can be removed from tools and equipment with acetone.

Available Sizes:

Gallon, 4 Gallon

Drums are available. Please call for pricing.

Handling and Storage:

Closed containers should be stored in a cool, dry place. It should be stored at temperatures below 75°F and away from sunlight and heat sources.

Vinyl Ester Laminating Resin should be used within 3 months of purchase.